“No second time has nature concentrated such an abundance of the most valuable nutrients in such

a small space as it did with the cocoa bean.”

- Alexander von Humboldt (1769-1859), naturalist -

What Is Cacao?

Cacao is made from the edible seed of the Theobroma Cacao tree. Cacao grows in tropical forests around the world, from South America to Africa and South East Asia.

What Is Raw Cacao?

Conventionally, cacao beans are roasted at high temperatures to manipulate the taste of the beans. But at UBUD RAW, freshly harvested cacao beans are fermented, and then dried at low temperatures, but they are never roasted.

This is because keeping cacao in its raw state preserves vital nutrients and live enzymes, maintaining an abundance of fiber and minerals such as zinc, magnesium & calcium, as well as vitamins B1, B2, B3, B5, B9 and E, and essential heart-healthy fats,

including a monounsaturated fat known as oleic acid.

Raw cacao also has the highest antioxidant value of any natural food in the world, and up to four times higher than in roasted cacao. The nutrients found in raw chocolate have been linked to a number of health benefits, including reduced blood pressure and improved circulation, promoting cardiovascular function, neutralizing free radicals, aiding digestion, reducing inflammation and enhancing physical and mental well-being. Safe to say, raw cacao is one of the most powerful superfoods nature has to offer.

How Cacao Beans Are

Harvested And Fermented?

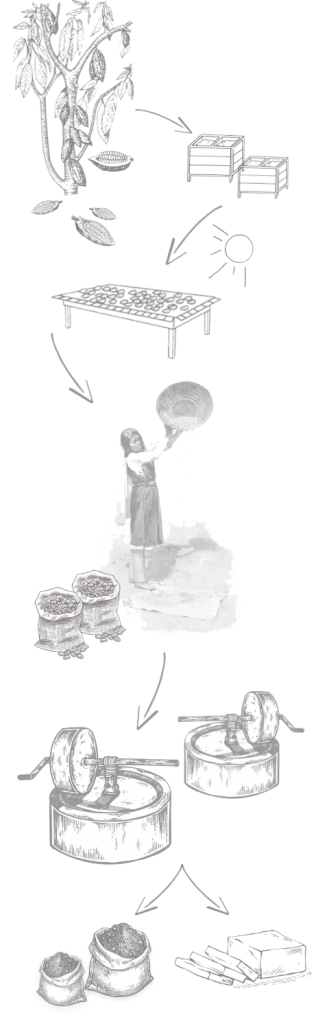

These seeds – or “beans,” as they are commonly called, are the primary ingredient in chocolate. They are harvested from the multi-colored fruit, or “pods,” which grow on cacao trees. A single cacao pod contains 20-60 seeds, which are embedded in a deliciously tangy sweet white pulp.

The pods are always carefully hand-picked in order to protect the trees from machinery. Once harvested, they are opened and the pulp-covered “wet beans” are removed. Then they go through a series of different processes before they are ready to be made into chocolate. Firstly, the wet beans are placed in special wooden boxes, where they are left to ferment for up to five days. At this point the beans turn brown and start to develop their special flavour. After fermentation, the beans are laid out in the sun to dry for 7-14 days. Approximately 2.5-3 kilograms of wet beans are needed to obtain 1 kilo of dried beans.

Winnowing The Beans

Once the beans are completely dry, they are broken into pieces and the shells are removed in the “winnowing” process, after which we are left with cacao ‘nibs’ – broken pieces of pure cacao.

From Cacao Nibs to Cacao liquor.

The nibs are put through a grinding machine to produce a thick liquid called cacao liquor, which hardens into blocks at room temperature. The grinding process can take hours, or even days, until the desired fine texture and flavor profile has been reached. This is also the stage at which sugar, milk, or various flavours can be added to make chocolate. At UBUD RAW, this pure raw cacao liquor is the base ingredient of all our raw chocolate.

Separating cacao liquor into cacao butter and cacao powder.

The cacao liquor can be pressed with heavy machinery until the oil separates. This golden or yellowish brown liquid cools to become what we know as cacao butter. What is left after this pressing process is cacao powder. 1kg of cacao liquor usually contains 45-55% of butter. But we can never fully separate all the fat from cacao powder. From 1kg of cacao liquor we can usually only make around 200-250g of butter. The rest remains part of the cacao powder. This is what makes cacao butter the most expensive part of the cacao.

These seeds – or “beans,” as they are commonly called, are the primary ingredient in chocolate. They are harvested from the multi-colored fruit, or “pods,” which grow on cacao trees. A single cacao pod contains 20-60 seeds, which are embedded in a deliciously tangy sweet white pulp.

The pods are always carefully hand-picked in order to protect the trees from machinery. Once harvested, they are opened and the pulp-covered “wet beans” are removed. Then they go through a series of different processes before they are ready to be made into chocolate. Firstly, the wet beans are placed in special wooden boxes, where they are left to ferment for up to five days. At this point the beans turn brown and start to develop their special flavour. After fermentation, the beans are laid out in the sun to dry for 7-14 days. Approximately 2.5-3 kilograms of wet beans are needed to obtain 1 kilo of dried beans.

Winnowing The Beans

Once the beans are completely dry, they are broken into pieces and the shells are removed in the “winnowing” process, after which we are left with cacao ‘nibs’ – broken pieces of pure cacao.

From Cacao Nibs to Cacao liquor.

The nibs are put through a grinding machine to produce a thick liquid called cacao liquor, which hardens into blocks at room temperature. The grinding process can take hours, or even days, until the desired fine texture and flavor profile has been reached. This is also the stage at which sugar, milk, or various flavours can be added to make chocolate. At UBUD RAW, this pure raw cacao liquor is the base ingredient of all our raw chocolate.

Separating cacao liquor into cacao butter and cacao powder.

The cacao liquor can be pressed with heavy machinery until the oil separates. This golden or yellowish brown liquid cools to become what we know as cacao butter. What is left after this pressing process is cacao powder. 1kg of cacao liquor usually contains 45-55% of butter. But we can never fully separate all the fat from cacao powder. From 1kg of cacao liquor we can usually only make around 200-250g of butter. The rest remains part of the cacao powder. This is what makes cacao butter the most expensive part of the cacao.

How To Use The Different

Forms Of Cacao?

In our online shop we offer raw cacao products in a wide variety of forms. Whether as a raw snack, as a topping, for making chocolate, for cooking, baking or for the preparation of natural cosmetics: our raw cacao is versatile and contains important nutrients that will help put you in a good mood! Here are a few application ideas at a glance:

Peeled Cacao Beans:

- To eat directly as a raw energy snack

- For decorating patisseries, or as a perfect accompaniment to wine

- and coffee pairing

- To process and grind to make your own nibs or chocolate

Cacao Nibs:

- As a topping for muesli, granola, smoothies and salads

- As a raw energy snack

- To grind for making your own chocolate

Cacao Liquor:

- For preparing raw desserts, or baking and cooking (hearty sauces become particularly interesting with the addition of cacao)

- For making chocolate

- For create a drinking chocolate, gelato, and ceremonial cacao

Cacao Butter:

- When making chocolate, we usually add a bit more cacao butter, as the high melting point ensures that chocolate bars snap nicely

- Is often used as a skin moisturizer and natural sunscreen for cosmetic products (body lotion, lip balm, sunscreen, etc.)

- As an alternative plant-based butter for cooking and baking

Cacao Powder:

- For making drinking chocolate and smoothies

- For baking and making desserts with chocolate flavors.

Organic Coconut Sugar:

- Not cacao, but a healthier alternative sweetener for your food and beverages (to replace white sugar or cane sugar)